A Challenge Rooted in Nature, Solved by Nature

In the heart of India’s thriving organic food processing sector, one fruit puree manufacturing company was struggling with a challenge faced by many in the industry: managing high-load effluent waste.

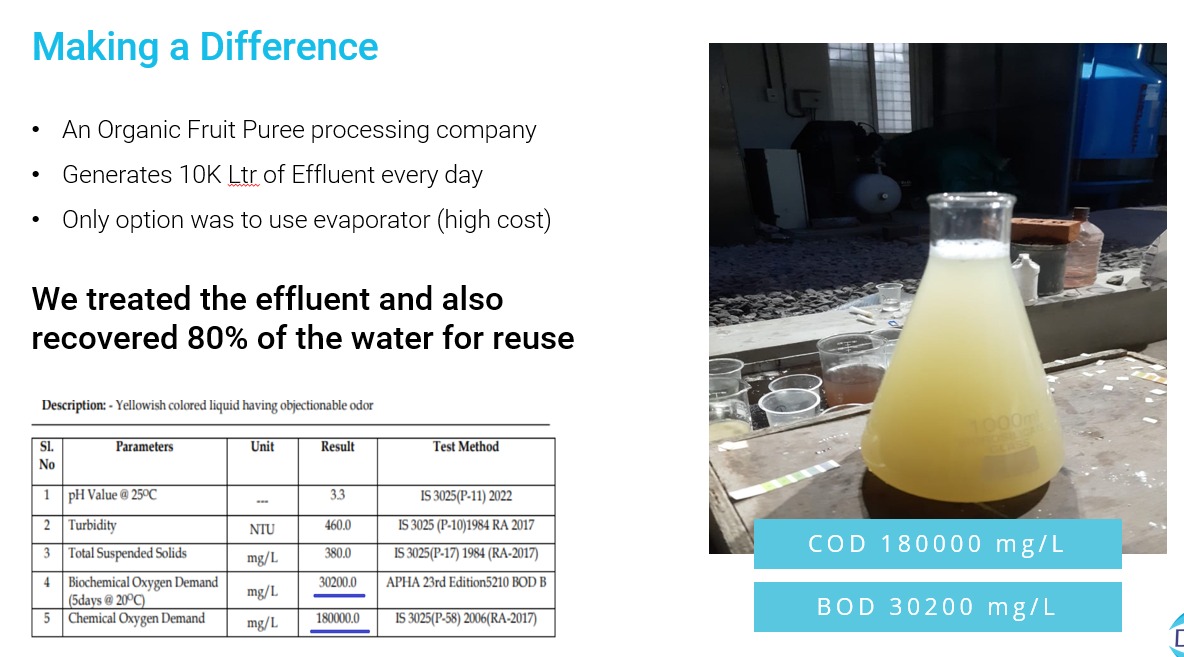

Processing nearly 10,000 liters (10K Ltr) of effluent every day, the company was confronted with an increasingly expensive and unsustainable problem. This effluent-rich in fruit pulp residues, sugars, and organic acids-had alarming contamination levels, including:

-

BOD: 30,200 mg/L

-

COD: 180,000 mg/L

-

pH: 3.3 (highly acidic)

-

Turbidity: 460 NTU

-

TSS: 380 mg/L

These levels posed serious environmental concerns, made regulatory compliance difficult, and imposed a financial burden through costly evaporator-based treatment and chemical-based solutions.

The Turning Point: When Traditional Methods Fail

Until recently, the only viable solution was to use a mechanical evaporator-a method not only energy-intensive but also burdened with high operational costs. Moreover, traditional chemical coagulants introduced risks of residual toxicity, chemical sludge generation, and long-term ecological damage.

It became evident: the fruit processing facility needed an innovative, sustainable, and cost-efficient wastewater treatment system.

DEUR’s Sustainable Intervention with HERBX

Enter HERBX, a plant-based, zero-chemical bio-coagulant offered by DEUR-a game-changer in the domain of food processing factory wastewater treatment.

By deploying HERBX at the site, DEUR enabled the company to shift from energy-hungry machinery and synthetic chemicals to a nature-powered solution that delivered results beyond expectations.

What HERBX Achieved:

-

80% Wastewater Recovery for internal reuse

-

Zero Chemical Usage — completely biological treatment

-

Significant COD & BOD Reduction

-

Drastic Cost Savings on energy and maintenance

-

No Harmful Byproducts or chemical residues

-

Environmentally compliant and scalable solution

Before & After Snapshot

| Parameter | Before Treatment | Post HERBX Treatment |

|---|---|---|

| Biochemical Oxygen Demand | 30,200 mg/L | Reduced significantly |

| Chemical Oxygen Demand | 180,000 mg/L | Reduced significantly |

| pH | 3.3 | Near neutral |

| Turbidity | 460 NTU | Within acceptable limits |

| TSS | 380 mg/L | Reduced |

| Water Recovery | 0% | 80% |

| Chemicals Used | High | Zero |

A Blueprint for the Future of Industrial Wastewater Treatment

This successful transformation shows how wastewater from food factories, especially in fruit puree industries, can be treated efficiently without chemicals, expensive evaporators, or environmental compromise.

By deploying a wastewater recovery plant using HERBX, this fruit puree company not only reduced pollution load, but also reused most of its water, closing the loop in their production process.